Synopsis: In a strip mall lies a culinary spectacle: The Indigo Restaurant. With its open kitchen, it draws you in from the inside and keeps you intrigued throughout your entire meal. The delicate lighting makes it a rich experience for any customers. The design process was economically viable while using the budget smartly, selecting materials carefully for an incredible finished product.

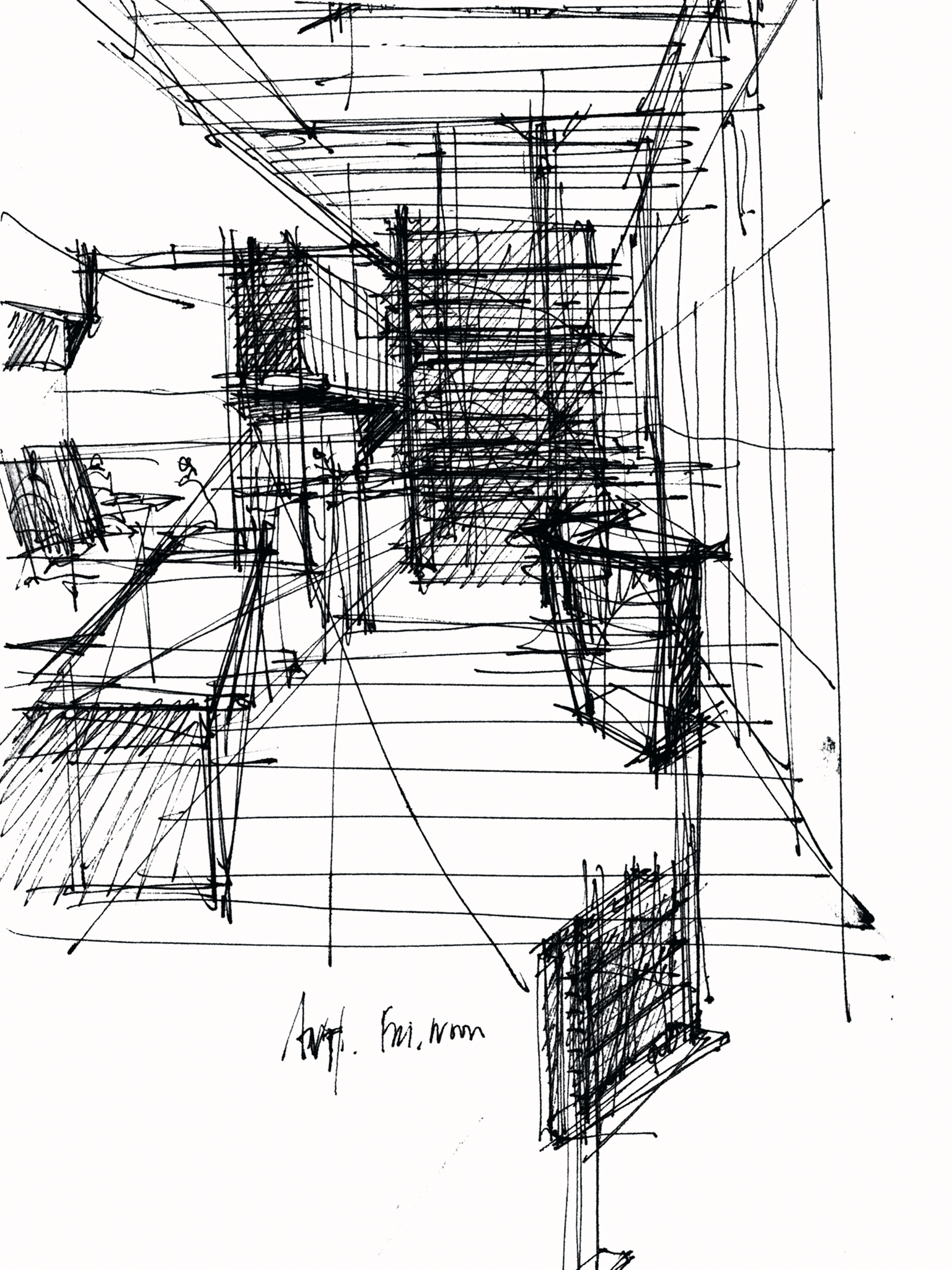

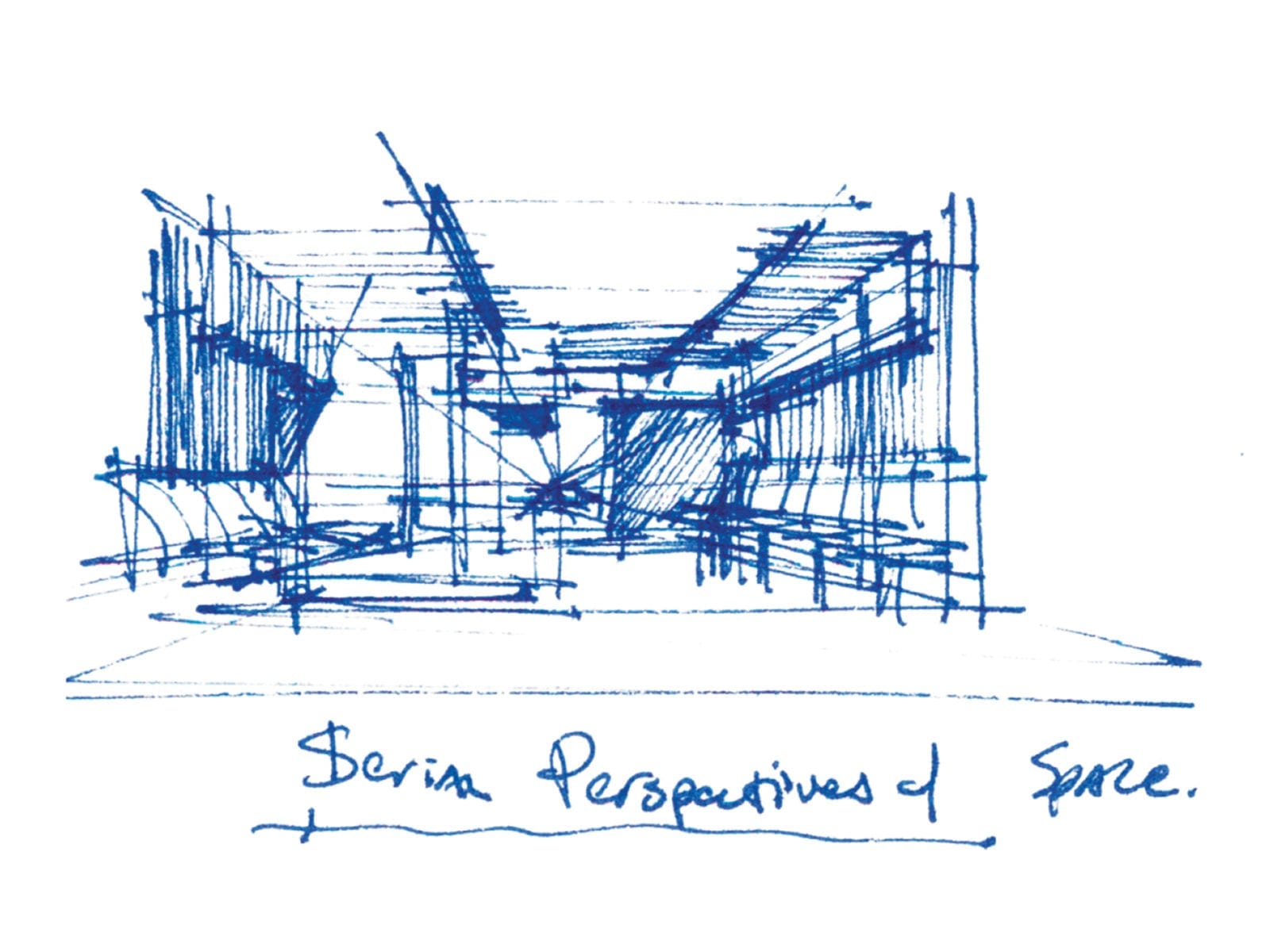

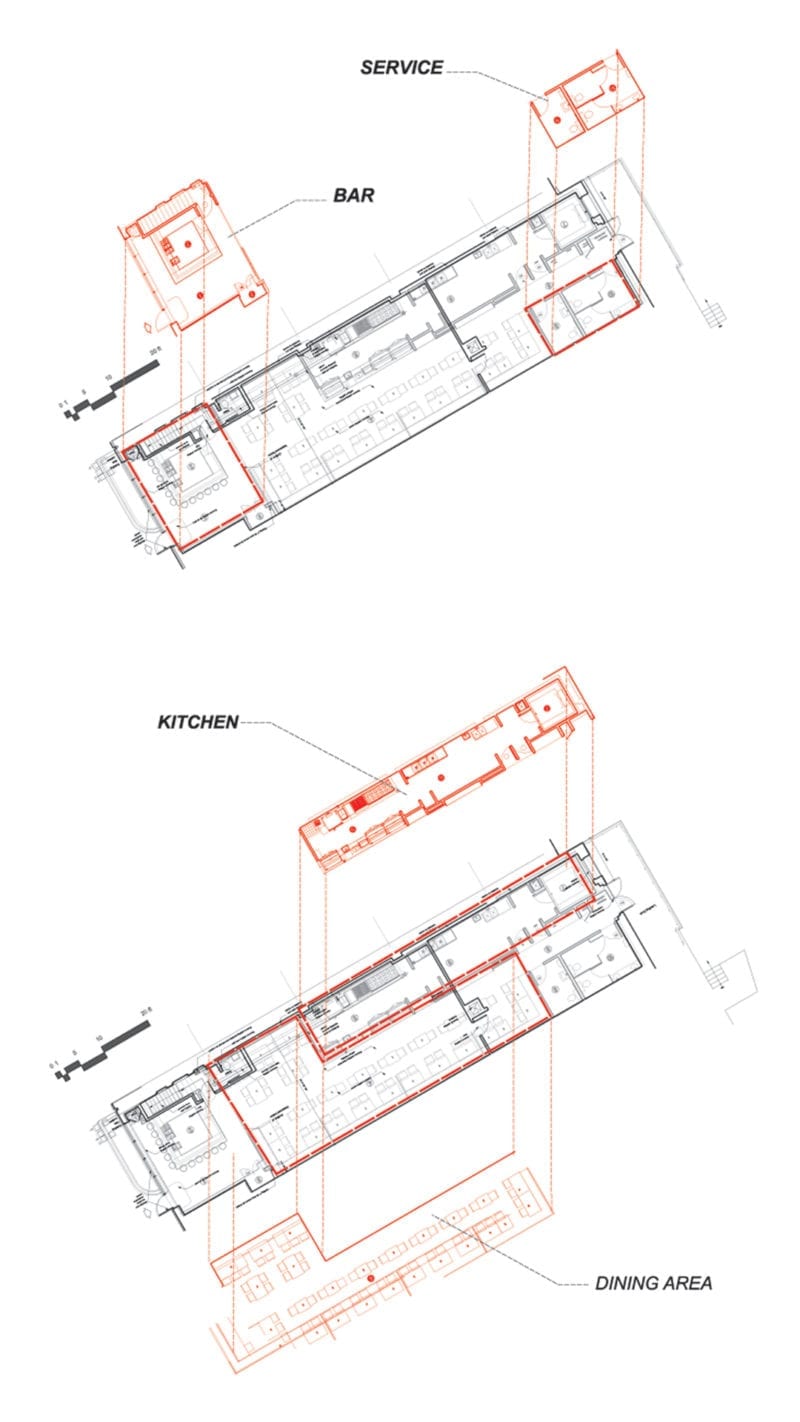

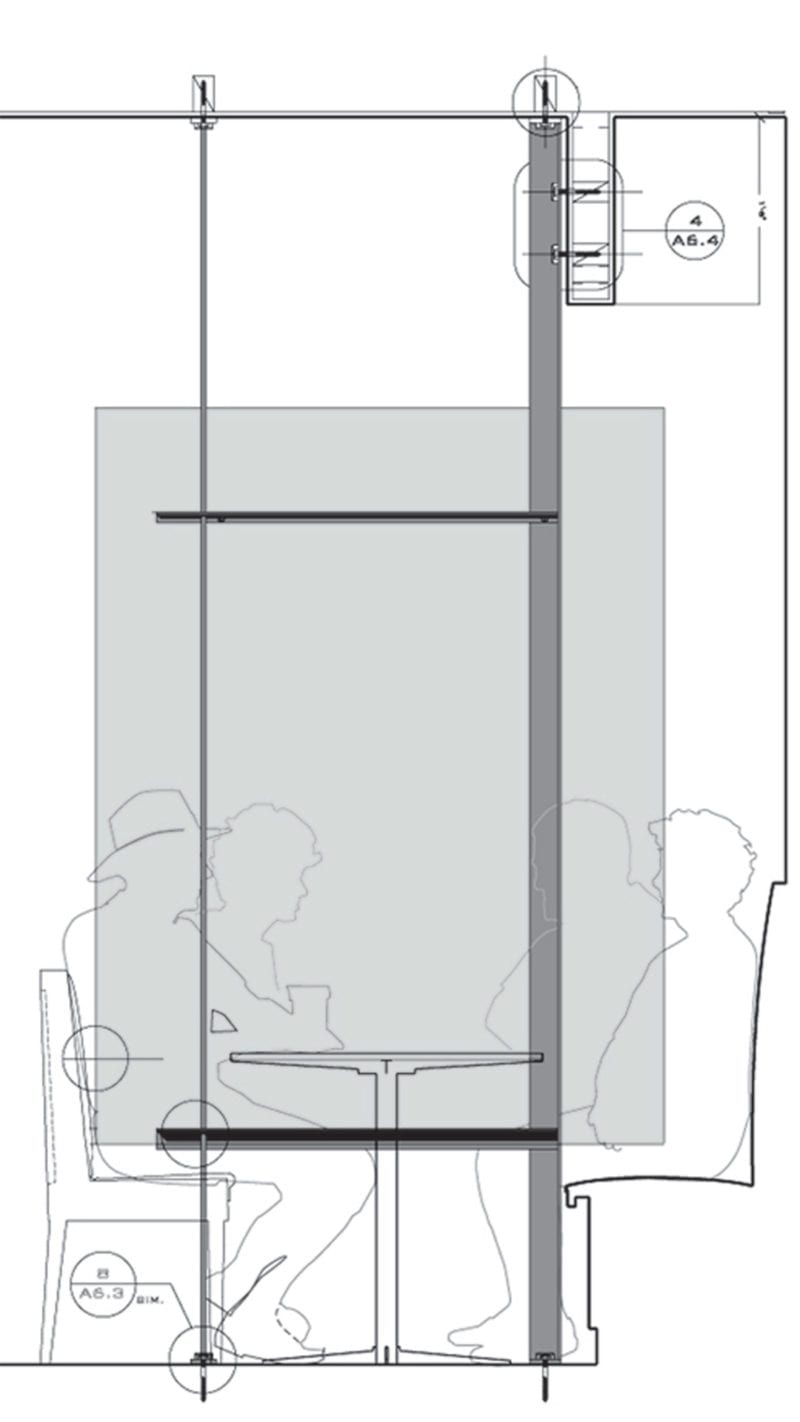

Detailed Description: The Indigo Restaurant seduces the visitor to engage in a visual culinary spectacle. The restaurant’s design attempts to buffer the harshness of the street and the nondescript mall through a sequence of layered spaces. The original building’s long, narrow volume is compartmentalized into a series of defined spaces that are visually connected to adjacent ones. These spaces and the partial views of the “open kitchen” are revealed sequentially and defined by custom-crafted steel screens, sandblasted glass, and changes in wall and ceiling surfaces. The varied palette of color, lighting, and material (acid-treated copper, beechwood, aluminum, granite, steel, rich fabrics) is choreographed to create a rich visual experience. Thus, visitors move with ease from space to space, each containing its own visual attractions until they are removed from the outside world.

With a tight budget of $250,000 ($125,000 was designated for kitchen equipment, leaving the remainder for interior finishes, furniture, lighting, mechanical systems, etc.), this project entailed building out the shell as economically as possible while retaining some budget for the selective use of special materials (copper, wood) and the fabrication of steel and glass installations. For instance, the use of $15 Stonco fixtures for indirect lighting (concealed behind baffles and lighting coves) saved money.

A $7K budget was set aside for the steel fabrications (six screens, entrance desk, steel column, wine rack), which were completed in collaboration with an artist/ironworker using steel components laser-cut from cad files of our 3D digital models. Through multiple iterations of design and value engineering, each screen was reduced to a minimum number of elements and connections, so we created the hostess station for $400.